Packaging is not an afterthought—it’s a strategic decision that shapes both product integrity and brand value. For specialty coffee roasters, the bag is far more than a vessel; it’s a preservation system, a merchandising tool, and a silent brand ambassador on every shelf. Every roaster who’s lost a shipment to bag deformation or had a retailer reject a shipment for inconsistent labeling knows — packaging choices ripple far beyond the warehouse. Among all formats, flat bottom coffee bags (also known as box pouches) have evolved from niche innovation to the industry’s preferred standard. Their rise isn’t about aesthetics alone, but about performance: superior shelf stability, efficient packing density, strong visual consistency, and compatibility with advanced multi-layer barrier films. These characteristics translate directly into fewer quality claims, better inventory management, and higher retail acceptance.

Every roaster eventually confronts the same question—how to package coffee in a way that safeguards flavor integrity, elevates presentation, and keeps costs under control. Stand-up pouches may offer lower entry costs but often compromise on structural stability and premium shelf impact. Rigid boxes, on the other hand, present a luxury image yet inflate total cost and logistics complexity. Flat bottom coffee bags have emerged as the equilibrium point, delivering the clean geometry and upright stance of a box without its material waste, while maintaining the cost efficiency of flexible packaging.

For emerging and established roasters alike, this format bridges technical reliability and commercial pragmatism. It’s not just a trend—it’s a measurable shift backed by data and market adoption. Before switching, treat it as a procurement initiative: define your performance criteria, run pilot batches, and match bag specifications with your roast volumes and distribution channels. Understanding why flat bottom coffee bags dominate the specialty segment begins not with design trends, but with quantifiable outcomes.

Market Context That Matters for Procurement

Understanding the shift toward flat bottom coffee bags requires more than just evaluating design trends—it’s about reading the market trajectory. The global flat bottom bags market is projected to grow from USD 1.6 billion in 2025 to USD 2.6 billion by 2035, at a CAGR of 4.7%, according to Future Market Insights. Plastic-based laminates are expected to retain a 61.5% market share, while the 50–150 oz capacity range—a segment that overlaps strongly with coffee packaging—will account for nearly 48% of total demand. This data signals not only growth but also consolidation: the industry is aligning around formats that optimize both cost and visibility.

For coffee roasters, this market momentum translates into real procurement signals. Suppliers are prioritizing R&D for high-barrier, flat bottom-compatible films, and automated filling lines are increasingly calibrated to handle this bag structure. As a result, unit prices are stabilizing while customization options are expanding—making the format more attainable for small and mid-sized roasters that once considered it a premium-only choice.

At the same time, retailers and distributors have begun standardizing shelf layouts around upright, box-like profiles that display logos cleanly and maximize facing area. In export-driven markets such as the EU and Australia, importers are even beginning to specify “flat bottom” or “box pouch” formats in RFPs due to their superior stackability and retail readiness. What began as a design preference has matured into a procurement benchmark, shaping how packaging buyers frame their specifications and negotiate supplier terms.

In other words, the rise of flat bottom coffee bags isn’t a creative trend—it’s a supply chain alignment. The data shows where the market is heading, and smart roasters are already adjusting their sourcing strategies to stay ahead.

For buyers, these numbers mean one thing: the format is no longer experimental. It’s becoming the benchmark that defines retail readiness.

Quantified Advantages: Unit Cost, Storage Efficiency, and Shelf Life

In packaging decisions, data speaks louder than intuition. Flat bottom coffee bags have earned their reputation not just for their appearance, but for their measurable impact on cost, logistics, and product preservation — all areas that matter to roasters managing real-world operations.

At first glance, flat bottom coffee bags can appear 10–20% more expensive per unit than standard stand-up pouches, largely due to their multi-panel construction and higher film usage. But that difference fades once efficiency and product value enter the equation. Many roasters report a 5–8% drop in logistics costs per kilo after switching, thanks to tighter packing density and fewer damaged bags in transit. For those selling through retail channels, the improved presentation often boosts sell-through rates by 8–12%, effectively offsetting the higher material cost. For mid-sized or export-oriented roasters, this margin recovery isn’t theoretical — it’s the kind of improvement that compounds month after month.

From a warehouse or export perspective, geometry is economics. Flat bottom coffee bags typically improve pallet density by 12–18%. For exporters, that’s not just a percentage on paper — it can mean fitting one extra pallet per container, directly reducing freight costs. The stable base supports vertical stacking without deforming the product, simplifying both warehouse handling and shelf display. For logistics teams managing consolidated shipments, this optimization often translates to savings of USD 300–500 per 20-foot container — a subtle but consistent operational edge that adds up over time.

Performance continues beyond shipping. The bag’s structure distributes tension evenly along sealing lines, reducing the chance of micro-leaks that could compromise aroma and freshness. When combined with high-barrier films like PET/AL/PE or recyclable EVOH laminates, oxygen transmission rates (OTR) can stay below 0.3 cc/m²/day, maintaining flavor integrity for up to 12–14 months under proper storage. Standard pouches, in comparison, often show flavor degradation 2–3 months earlier.

Across every variable — cost, space, and shelf life — the pattern is clear. Flat bottom coffee bags deliver tangible efficiency gains and predictable returns, allowing procurement teams to model ROI in practical terms: lower storage overhead, stronger retail visibility, and longer-lasting freshness that customers can actually taste.

How Flat Bottom Bags Improve Commercial Outcomes

For most roasters, switching packaging formats isn’t about design preference—it’s about what actually moves the business. Packaging affects efficiency, cost, and perception, and flat bottom coffee bags have quietly become a structural advantage across all three.

In retail, first impressions sell faster than tasting notes. Flat bottom bags stand upright with precision, giving every SKU the posture of a premium product. Eye-tracking tests in cafés and grocery shelves show 25–30% longer visual dwell time than flexible pouches, and that extra second often converts into trial. One Northern European roaster saw a 9% rise in average unit price after adopting matte flat bottom pouches, with no dip in volume. It wasn’t design for design’s sake—it was margin recovery through presentation.

Beyond the shelf, filling performance drives the real ROI. The stable base and wider mouth of flat bottom bags improve fill accuracy by up to 15%, especially on nitrogen-flushed or high-density lines. In co-packing facilities, operators report around 10% lower film waste and fewer line interruptions than side-gusset formats. Those aren’t small gains; across tens of thousands of units, that’s hours of uptime and thousands of dollars back to the bottom line.

Across hundreds of roaster case studies, one pattern keeps appearing: once the format changes, the numbers move—faster filling, cleaner shelves, fewer damaged shipments. That’s not theory; it’s operations data.

For exporters, geometry translates directly to cost. The rectangular profile of flat bottom bags allows tighter pallet stacking, often adding one full layer per stack compared with stand-up pouches. Over a 40-foot container, that’s up to 2,000 additional retail units shipped without exceeding weight limits. The structure also reduces crushing during transit, protecting valve integrity and ensuring the product arrives shelf-ready. One Southeast Asian roaster shipping to Australia cut damage-related complaints by 20% after switching, simply because the bags held their shape better.

But the real leverage comes from storytelling. With five printable panels, flat bottom coffee bags give brands the space to communicate origin, process, and sustainability without visual clutter. In a 2024 survey, 68% of roasters said layout directly shapes how they present farm details to consumers. That extra space doesn’t just make packaging look better—it makes it shareable. Many specialty cafés now feature packaging photos in their digital campaigns, turning physical design into organic online exposure.

Flat bottom coffee bags are not a luxury upgrade. They’re a commercial tool that protects quality, drives efficiency, and lifts brand perception—all measurable outcomes. For smaller roasters, they bridge artisanal identity with scalable logistics. For established exporters, they’re the geometry of global efficiency.

Procurement Playbook: Specs, Tests, and RFP Essentials

Choosing the right flat bottom coffee bag supplier isn’t just a sourcing task, it’s a decision that shapes how your product performs on the shelf and how your brand is perceived in the market. Too many roasters still judge packaging by looks or price alone. In reality, the right bag delivers consistency, protects flavor, and prevents the kind of quality claims that quietly eat into your margins. Treat it like a technical investment, not a visual one.

Start by asking for proof, not promises. Flat bottom bags can be made from PET/AL/PE, MOPP/PE, or recyclable PE monostructures. Each structure affects oxygen and moisture resistance differently. Don’t just accept “high barrier” as a label—ask for OTR (oxygen transmission rate) and MVTR (moisture vapor transmission rate) reports. Anything below 1.0 cc/m²/day works for roasted coffee; below 0.3 is ideal for longer storage or export shipments. These aren’t just lab numbers—they directly affect how your coffee tastes months later.

Next, check how the bag holds up in real conditions. Poor sealing or weak gussets cause deformation and air leaks during transport. A good supplier should test every new run with a 1-meter drop test and valve leakage check. Don’t take their word for it—ask for short production pilots of 500–1000 bags. You’ll quickly see which suppliers can keep shape, sealing yield, and print alignment consistent batch after batch.

Then, put clarity into your RFPs. Instead of vague specs, write what matters: laminate type, thickness tolerance (±5–10 μm), bag size variance (±2 mm), valve position accuracy, and sealing defect tolerance (<1%). If you use nitrogen flushing or need metal detection compatibility, say so upfront. It’s not about paperwork—it’s about protecting yourself from hidden costs later, when shipments fail QC or can’t pass customs.

Compliance matters too. For EU-bound shipments, make sure the supplier can show migration safety per EU 10/2011. In the U.S., look for FDA-compliant food-contact materials and BPI or SPC sustainability certifications. In Asia-Pacific, many retailers now require recyclability marks or “OK Compost” logos on printed packaging. The earlier these details are aligned, the faster you move from prototype to production without delays.

And here’s a simple rule that separates good procurement from great procurement: stay in touch after the first delivery. Packaging suppliers should act like technical partners, not one-time vendors. When you test a new degassing valve or print finish, invite them to join your QA check. Keep a shared log of sealing yields, print deviations, and handling feedback. Over time, that shared data builds leverage—you’ll negotiate better pricing because you can prove performance trends instead of debating them.

If you’re a growing roaster, this may sound like a lot of work. But it’s exactly how the most reliable coffee brands scale. They don’t win because they buy the cheapest bags; they win because they manage packaging as part of their production system. Flat bottom coffee bags fit perfectly into that mindset: strong, predictable, and built to perform—not just look good. When your packaging works this smoothly, it becomes invisible. That’s when you know it’s done right.

Scenario Guidance: Small, Medium, and Export-Oriented Roasters

Choosing a packaging format is never a one-size-fits-all decision. For a local roaster with direct-to-consumer focus, agility often matters more than unit efficiency. A stand-up pouch allows flexible batch runs, quick design refreshes, and low setup costs — ideal for subscription models or seasonal blends where speed and variety outweigh long-term display stability. But once a roaster begins scaling into retail shelves or wholesale channels, the same convenience can become a limitation. Bags that lean or deform after filling can disrupt shelf presentation, dilute brand consistency, and create uneven pallet stacking, which adds hidden costs in logistics and storage.

This is where flat bottom coffee bags reveal their true value. The box-shaped base provides a rigid, self-standing structure that optimizes visibility and space utilization, while their five-panel design gives roasters more real estate for storytelling, brand differentiation, and compliance labeling. It’s a practical upgrade that bridges small-batch creativity with the disciplined requirements of larger retail distribution. Unlike premium box pouches that often require costly tooling or complex lamination layers, flat bottom bags balance manufacturing efficiency with high-end aesthetics. For growing roasters, that balance translates into predictable margins without compromising the tactile or visual quality that consumers associate with craft products.

Even established brands find that switching to this format can rationalize their portfolio. When SKUs multiply and demand consistency across different markets, a single bag type that fits multiple fill weights and sealing options simplifies operations. A flat bottom bag works across degassing valve systems, nitrogen flushing setups, and automated filling lines — minimizing changeover time and reducing the risk of misalignment between packaging design and production capacity.

Ultimately, the right packaging format depends on where a roaster stands in their growth curve. But for many, flat bottom coffee bags represent a convergence point — a format that feels premium yet remains commercially efficient, grounded in both design logic and operational discipline.

In the end, flat bottom bags aren’t just a packaging upgrade — they’re the point where craftsmanship meets commercial maturity.

Compliance & Market Differences: EU, US, and Asia

Compliance expectations also differ sharply across markets, and understanding these nuances often determines how well a roaster’s packaging strategy scales internationally. In the European Union, sustainability is no longer a marketing angle but a legal framework. The Packaging and Packaging Waste Regulation (PPWR) and the Single-Use Plastics Directive are setting measurable targets for recyclability and compostability. For flat bottom coffee bags, this means more than using “eco-friendly” films — materials must demonstrate compliance with EN 13432 or CEN/TC 261 standards to be accepted in most EU import systems. Roasters targeting Europe increasingly favor mono-material PE or certified compostable laminates that can maintain barrier performance while meeting circular economy criteria.

In the United States, the landscape is less centralized but commercially influential. Instead of unified regulation, pressure now comes from major retailers and state-level initiatives. Many national chains have aligned with the Sustainable Packaging Coalition (SPC) guidelines, and BPI-certified compostable labeling is quickly becoming a standard benchmark for credibility. For roasters selling through online subscriptions or direct-to-consumer models, resealable mono-material PE or kraft-paper laminates have become the default choice — balancing sustainability messaging with operational efficiency and recognizable consumer cues.

Across Asia-Pacific, regulations remain comparatively flexible, but consumer behavior is shifting faster than policy. Markets such as Japan, South Korea, and Singapore are redefining premium packaging aesthetics, blending recyclability with tactile quality. Export-oriented roasters who treat these regions as early adopters of “eco-premium” trends are often better positioned for long-term growth. In these markets, a flat bottom coffee bag that feels refined yet communicates environmental awareness can bridge the perception gap between Western sustainability narratives and Asian design sensibilities.

Suppliers like FernPack already align their materials portfolio with these evolving regional standards, helping roasters simplify compliance while maintaining global consistency.

Supplier Quality and Governance Essentials

Any supplier can promise quality — few can prove it lot by lot. That’s where real governance begins. Price tells you little about long-term reliability; what matters is control — over process, over testing, and over traceability. For coffee roasters shipping across regions, the difference between a good supplier and a dependable one is measured not in cents per bag, but in how consistently those bags perform after months on a retail shelf.

Start with traceability. Every roll of laminate, every batch of ink or degassing valve should be recorded and traceable. When a print defect or odor issue arises, you need to know exactly where it came from. Reliable suppliers can show you that data without hesitation.

Testing tells the rest of the story. Trust the ones who run oxygen and moisture barrier tests (OTR and WVTR) in-house — not just in brochures. The best facilities conduct drop and compression trials before every shipment. Certifications like ISO 22000 or BRCGS are good indicators, but internal discipline matters more than logos on a wall.

Even after delivery, verification shouldn’t stop. Randomly checking 2–3% of each lot for seam strength, valve placement, and print accuracy gives you the data to hold partners accountable. Maintaining a simple supplier scorecard doesn’t just prevent failures — it builds leverage during negotiations, ensuring quality and cost stay aligned.

Strong supplier governance isn’t bureaucracy. It’s what keeps your packaging program predictable, efficient, and credible — so you spend less time fixing problems, and more time building a brand that customers trust.

Quick Decision Checklist: How to Know If You Should Switch

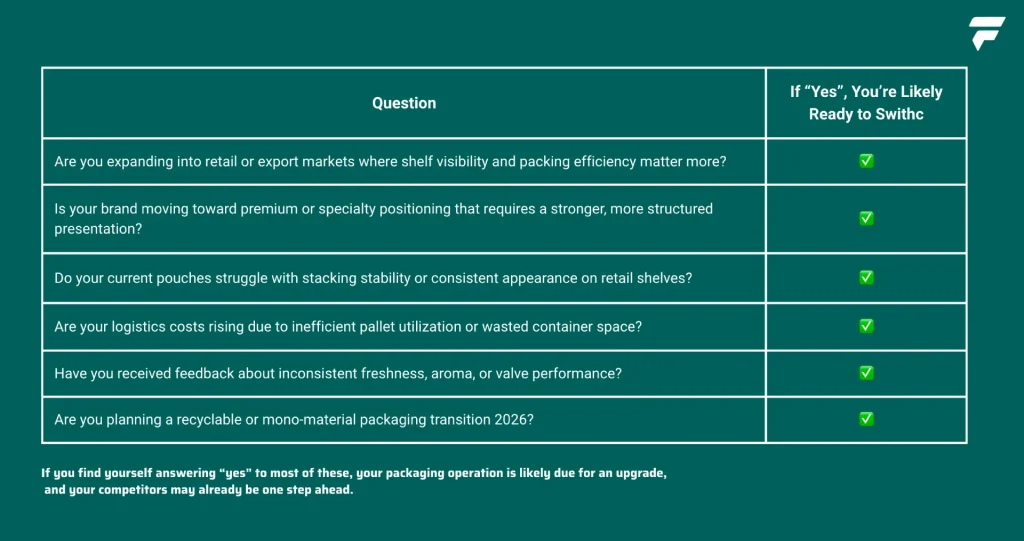

Before upgrading your packaging line, assess where your business currently stands. These indicators can help determine whether flat bottom coffee bags are the right move for you:

If you find yourself answering “yes” to most of these, your packaging operation is likely due for an upgrade — and your competitors may already be one step ahead.

From Pilot to Full Rollout: Executing the Transition

Once the decision to adopt flat bottom coffee bags is clear, the next challenge is execution. Transitioning packaging formats is less about replacing materials and more about synchronizing procurement, design, and operations. A phased rollout ensures minimal disruption and measurable improvement.

Phase 1: Pilot and Validation.

Start with one or two SKUs representing your typical fill weight and shelf exposure. Conduct a controlled trial — 1,000 to 3,000 units — and monitor three metrics: fill accuracy, degassing valve performance, and end-customer feedback. Gather data on shelf presentation and transport compression. These small-scale results will tell you more about performance than any brochure or supplier claim.

Phase 2: Supply Chain Alignment.

Once validated, extend specifications to your filling partner and logistics provider. Align carton dimensions and pallet stacking patterns to leverage the bag’s box-like geometry. Many roasters underestimate this step, yet optimizing outer packaging can improve container utilization by 8–12%, directly reducing freight costs. Confirm that film and ink lots are traceable, and that QA samples are retained for post-shipment verification.

Phase 3: Brand and Market Rollout.

Integrate the new format into your brand narrative — not as a design change, but as a performance upgrade. Highlight freshness retention, structure, and environmental options in your marketing and sales material. Specialty buyers appreciate transparency; even a brief mention of barrier properties or reduced waste can differentiate your product in competitive shelf spaces.

Phase 4: Continuous Improvement.

Within three months of rollout, review returns, customer feedback, and operational KPIs. Track how the switch affected your shelf-life claims, defect rates, and freight cost per unit. Use these metrics to fine-tune your next production run. Over time, the combination of structural integrity, visual uniformity, and measurable logistics gains becomes part of your brand’s operational advantage — not just an aesthetic one.

Flat bottom bags are not a cosmetic choice; they represent a quiet systems upgrade that links marketing, supply chain, and quality assurance. Treating packaging as an iterative process, rather than a one-time decision, is what ultimately separates roasters who grow sustainably from those who merely adapt to trends.

As automation and sustainability continue to reshape packaging, flat bottom coffee bags will remain the format that adapts — not reacts. The brands that master it today will define tomorrow’s retail landscape.

Closing: Packaging as a Strategic Asset

Flat bottom coffee bags are no longer a design trend; they represent a mature equilibrium between function, form, and financial sense. The global market’s steady 4.7% CAGR reflects more than demand growth — it signals an industry realignment toward packaging that serves both operational efficiency and brand integrity.

For specialty roasters, the shift to flat bottom bags is not just about changing shape. It’s about recognizing packaging as a silent strategy — one that influences freshness, logistics, shelf appeal, and customer trust in equal measure.

👉 Ready to Explore Your Options?

Visit FernPack’s Flat Bottom Coffee Bags Collection, Or You can build your own bag from our official link.

Discover structures, barrier options, and custom printing tailored to your roast and market goals.