Vacuum sealed bags provide a good guarantee for green coffee beans. Because green coffee beans are not inert commodities. They are biologically active, hygroscopic, and highly sensitive to environmental exposure. Improper storage can result in moisture absorption, aroma loss, and overall degradation in cup quality. These risks are magnified during long-haul exports and extended warehousing, especially under fluctuating climate conditions.

This makes export-grade packaging a critical factor—not just in logistics, but in protecting product integrity and delivering on quality expectations. For B2B buyers such as importers, specialty roasters, and green coffee traders, packaging choices can directly influence value retention, roasting consistency, and client satisfaction.

Traditional solutions like jute sacks and GrainPro liners offer some degree of protection, but increasingly fall short when dealing with high-end or climate-sensitive coffees. Vacuum-sealed green coffee bags, such as those available at FernPack (Vacuum-Sealed Coffee Bags), are now widely recognized as the benchmark for safeguarding specialty-grade lots during transit and storage.

So what exactly makes vacuum-sealed coffee packaging different—and when is it worth the investment?

Common packaging options in the market (and their limitations)

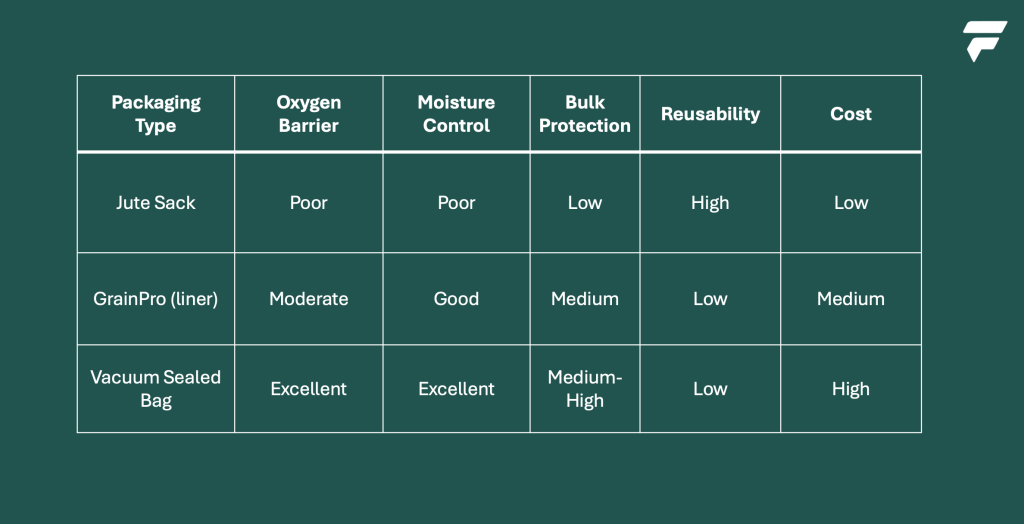

Before understanding why vacuum-sealed bags are gaining traction, it’s important to recognize the shortcomings of traditional packaging options:

- Jute sacks, though cost-effective and breathable, offer little protection against moisture, oxygen, or pests. Beans stored in jute are more susceptible to mold growth, loss of aromatic compounds, and degradation during transit.

- GrainPro liners, typically placed inside jute sacks, improve moisture resistance but still allow for oxygen exposure. They are a compromise solution but not suitable for high-end or delicate coffees.

For high-value coffee exports, long-term storage, or sensitive lots, these solutions often fall short—establishing the need for vacuum-sealing as a more robust preservation method.

The science behind vacuum sealed bags: less oxygen, more stability

The value of vacuum-sealed packaging for green coffee is grounded in established food science and quality assurance protocols, particularly regarding oxidation and moisture control. Though green beans are dormant, they remain biologically active and vulnerable to ambient oxygen and humidity, both of which accelerate biochemical degradation during coffee export.

Vacuum sealing eliminates oxygen within the bag, significantly slowing oxidative reactions. For example, Selvakumar et al. (2023) in the Journal of Food Science and Technology showed that reducing oxygen exposure can preserve chlorogenic acids and volatile aroma precursors. These compounds are vital for maintaining the green coffee’s sensory potential over time.

Humidity stability is equally critical. A study published by the Specialty Coffee Association (SCA, 2022) found that vacuum-sealed beans experienced less than 1.5% moisture gain over six months in fluctuating conditions, compared to over 4% in jute or PE-lined packaging. This reduction in moisture ingress curbs mold development, fermentation off-notes, and premature flavor degradation. Internal quality lab reports from several large importers confirm that vacuum-packed lots maintain higher scores across 9–12 months of storage.

Moreover, color stability and roasting predictability are enhanced, contributing to more consistent performance across production batches. For producers, this means delivering coffee that meets buyer expectations even after long transit times. For importers and roasters, it means better inventory planning, lower rejection risk, and more accurate profiling.

Vacuum sealing is particularly impactful when used for:

- High-altitude micro-lots: These tend to have fragile aromatics and are highly sensitive to oxygen.

- Competition or reserve lots: Where sensory excellence is paramount and slower turnover is common.

- Export routes involving sea freight: Especially those subject to long transit times and humidity fluctuations.

These use cases underline the practical benefits and reinforce vacuum packaging not as a trend, but as a technically sound, performance-driven investment in quality retention.

Vacuum sealed bags vs other export packaging options

Let’s break down how vacuum sealed green coffee bags compare to other common packaging types:

Jute sacks offer breathability but expose beans to fluctuating moisture and contaminants. They are suitable for short-haul domestic logistics but problematic for premium coffee exports.

GrainPro liners, used inside jute sacks, improve moisture control but don’t remove oxygen. They provide a middle ground—cost-effective and practical, but not ideal for fragile micro-lots.

Vacuum-sealed packaging is superior when quality retention is non-negotiable. It does add cost and complexity (e.g., sealing machinery, packaging time), but its protective value outweighs these for specialty exporters.

Shelf life and sensory impact: does it really make a difference?

The preservation of sensory attributes in green coffee is more than a matter of taste—it carries measurable commercial implications. For specialty roasters and importers, flavor consistency is the foundation of customer trust and brand differentiation. Scientific investigations and industry cupping trials offer concrete evidence: vacuum-sealed green coffee retains its sensory attributes—such as florals, brightness, and a balanced acidity—for significantly longer periods compared to beans stored in traditional jute or even GrainPro packaging.

For instance, A 2021 comparative study conducted by the Brazilian Coffee Industry Association offers strong empirical evidence: identical lots of green coffee were stored for 12 months in three different packaging types—jute, PE-lined, and vacuum sealed bag. Over time, jute-packed samples showed a decline of 2–3 points in Q Grader evaluations within just six months, mainly due to moisture uptake and oxidation. In contrast, vacuum-sealed samples retained their quality with less than a 0.5-point variation for the entire year. This difference was not just anecdotal; it directly correlated with fewer lot rejections, greater sensory consistency, and more stable commercial outcomes. For decision-makers, this highlights how packaging isn’t merely a logistical concern—it plays a critical role in protecting the sensory and financial integrity of green coffee throughout the export lifecycle.

For roasters, this consistency supports operational planning: they can develop seasonal profiles with confidence, streamline inventory, and reduce flavor variability that could lead to customer dissatisfaction. Importers benefit from improved rotation cycles and reduced risk of loss from spoiled or downgraded lots.

Vacuum-sealing is also gaining traction at origin. Producers shipping reserve or microlot coffees to quality-focused buyers increasingly use vacuum as a way to demonstrate professionalism and safeguard value.

The bottom line is clear: vacuum-sealed packaging does not simply delay aging—it upholds cup quality, enables business continuity, and signals a commitment to excellence.

Logistics considerations: weight, handling, and palletization

For green coffee exporters and importers alike, logistics is where packaging decisions often prove their real-world value. Vacuum sealed bags, typically available in 15–20kg formats, contrast sharply with traditional 60kg jute sacks—not just in size but in handling, shipping efficiency, and cost implications.

Labor and Handling Efficiency: Smaller vacuum sealed bags are easier for warehouse staff to move and organize manually, reducing the need for forklifts or multi-person lifts. This can lower labor-related injury risks and improve packing speed, especially in origin warehouses or small-scale roasteries.

Pallet Configuration and Container Optimization: Due to their compact shape and uniform size, vacuum-sealed bags enable denser palletization. Compared to loosely stacked jute sacks, vacuum formats can fit up to 30–40% more green coffee per pallet, depending on stacking and pallet size. This has a direct impact on container usage:

- A 20-foot container can typically carry 10–15% more green coffee with vacuum-sealed bags.

- Better stackability means less wasted airspace and a lower risk of bag damage during transit.

Customs and Port Inspection Benefits: Clear labeling and tamper-evident seals streamline customs clearance and inspection. For export-oriented producers, this can shorten port turnaround times and reduce risk of delays.

Cost and Freight Impact: While the unit cost of vacuum packaging is higher—due to materials and sealing equipment—the savings on freight and storage can quickly add up:

- Reduced shipment frequency for the same volume of coffee

- Up to $500–$1500 saved per container in freight costs annually, depending on shipping lane, volume, and storage conditions

These benefits are particularly pronounced for high-value, low-volume lots that need reliable preservation and efficient global movement. For specialty buyers and regional distributors, improved space utilization translates into operational agility and lower landed costs.

Ultimately, the shift to vacuum-sealed bags should be viewed not only as a quality-preservation upgrade but also as a strategic logistical investment—especially for those moving microlots, reserve-grade coffees, or handling multiple smaller batches destined for varied markets.

Environmental trade-offs: is vacuum packaging sustainable?

Vacuum-sealed green coffee bags raise important questions around sustainability—particularly for B2B buyers aiming to align quality control with environmental responsibility.

These bags are typically constructed from multilayer plastic films (such as polyethylene-aluminum-polyester combinations), which are excellent at creating oxygen and moisture barriers. However, these materials are rarely recyclable through municipal systems due to their composite structure. As a result, most used bags end up in landfills or incineration streams, contributing to waste and greenhouse gas emissions.

From a carbon footprint perspective, vacuum packaging requires more energy and material inputs than jute or GrainPro options. Yet this impact must be weighed against the reduced losses from spoilage, mold, or quality degradation—factors that can drive inefficient use of shipped coffee and reordering emissions.

Sustainability efforts are emerging:

- Mono-material vacuum bags using recyclable polyethylene are in early-stage adoption.

- Some exporters and importers are piloting closed-loop return systems to recover and reuse vacuum bags from commercial roasters.

- Life cycle assessments (LCAs) are being developed to evaluate trade-offs between quality preservation and end-of-life impact.

The real-world sustainability of vacuum packaging also depends on how bags are disposed of—a challenge in countries with limited recycling infrastructure. For example, many importers in Europe or North America still lack scalable pathways to handle used multilayer films.

Ultimately, buyers should ask whether the quality protection justifies the environmental trade-off for each coffee lot. Transparent dialogue between origin and destination, and alignment on carbon priorities, will help ensure that vacuum packaging supports—not undermines—your brand’s sustainability goals.

Choosing the right packaging: questions to ask before you switch

Vacuum sealing isn’t always a one-size-fits-all solution. For coffee exporters and cooperatives, the decision to adopt vacuum packaging should be aligned with operational capabilities, target markets, and the unique attributes of the coffee being handled.

Before making the switch, evaluate the following considerations:

- What is the value of the lot? High-scoring or competition-grade coffees demand extra protection. Vacuum-sealing is often most justified for lots with significant market premiums or distinct sensory profiles.

- How long is the expected storage or shipping time? If green coffee will spend months in warehouses or transit—especially under variable climate conditions—vacuum-sealing can help ensure cup quality upon arrival.

- Who is your buyer, and what do they expect? Premium roasters and importers increasingly expect green coffee to arrive in peak condition. Vacuum packaging communicates professionalism and attention to quality.

- Are you handling micro-lots or experimental lots? These typically require more careful handling. Smaller volumes and higher risk of sensory degradation make them ideal candidates for vacuum-sealed formats.

- Does your facility support vacuum packaging? Beyond the equipment cost, consider staff training, sealing protocols, and batch-level traceability. Not all operations are ready for the change.

- What type of business are you?

- Large-scale exporters: Vacuum-sealing is ideal for flagship products and long-haul shipments that must maintain top-tier quality.

- Regional cooperatives: Consider vacuum packaging for competition lots, traceable microlots, or direct-to-roaster relationships where differentiation matters.

- Specialty importers: May require vacuum formats as a procurement standard, especially when sourcing from multiple origins with staggered harvests.

By assessing both internal readiness and market alignment, producers and exporters can determine whether vacuum-sealed packaging will enhance their value proposition—or become an operational burden.

Vacuum sealed bags: More than preservation—A competitive edge

Choosing vacuum-sealed packaging for green coffee is no longer just about freshness—it’s a strategic investment in consistency, reputation, and export reliability. For producers and exporters aiming to serve the specialty market, it sends a clear signal to buyers: this coffee is handled with care, precision, and long-term quality in mind.

Roasters, in turn, benefit from the downstream effects: more stable lots, longer planning horizons, and fewer quality surprises. Especially for seasonal or micro-lot profiles, this packaging enables better forecasting and cupping alignment across months.

As climate risks, transit delays, and customer expectations rise, vacuum-sealed formats are becoming an operational safeguard—not just a quality perk. The choice isn’t just about packaging material—it’s about protecting the value embedded in each bag, from farm to roastery.

If you’re considering a switch, ask: What does your current packaging say about your brand—and how much quality are you leaving to chance?

Ready to explore vacuum sealed solutions for your green coffee exports?

At FernPack, we work with producers, exporters, and roasters worldwide to tailor vacuum packaging to your logistics, quality, and sustainability goals. Whether you’re managing micro-lots or shipping full containers, we’re here to help you find the right fit.

Contact us today to request samples, specifications, or a custom quote.

All inquiries are answered within 24 hours by our product experts.