Drip coffee bags, also known as hanging-ear coffee bags, have moved beyond niche appeal to become one of the fastest-growing formats in specialty coffee. They sit at the intersection of modern convenience, single-serve precision, and premium brand perception, making them increasingly relevant to how consumers discover and experience coffee today.

For many roasters, interest in drip coffee bags begins with simple signals: repeated customer requests, demand for travel-friendly offerings, or the need to extend brand presence beyond the traditional café or retail shelf. What often comes later is the realization that producing a product this small and portable is far from simple.

Real success with drip coffee bags is not driven by coffee quality alone. It depends on how well material selection, sealing accuracy, oxygen control, and brewing consistency are aligned. When these elements work together, drip bags become a scalable, high-performing product line. When they do not, even excellent coffee struggles to deliver the experience customers expect.

Why are drip coffee bags becoming essential for modern roasters?

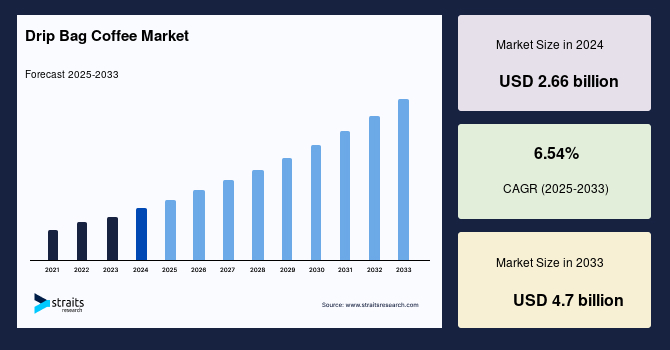

Drip coffee bags are no longer a novelty. They are increasingly becoming a strategic extension of a roaster’s product line, shaped by both shifting consumer behavior and clear market momentum. Globally, The Industry report from straitsresearch indicates that the drip bag coffee market was valued at approximately USD 2.66 billion in 2024 and is projected to reach USD 4.70 billion by 2033, growing at a steady CAGR of over 6.5%. This growth is not speculative. It reflects a structural change in how consumers access and consume specialty coffee.

Consumers increasingly expect high-quality coffee wherever they go: in airports, at the office, on hiking trails, or simply between daily activities. This shift toward convenience has redefined the expectations of portable specialty coffee. Drip bags deliver portion-controlled brewing with predictable clarity, satisfying this demand effortlessly.

Beyond convenience, drip coffee bags expand brand reach. Each bag becomes a small ambassador for your roast profile and brand story, traveling through gift sets, corporate programs, subscription boxes, pop-ups, hotel amenities, event giveaways, and café retail tiers. Unlike whole beans or standard ground coffee, a single bag can deliver a controlled, consistent taste of your brand in settings where other formats cannot. For many roasters, these touchpoints serve as effective customer acquisition channels, often outperforming traditional marketing tactics.

From a commercial standpoint, drip bags create high-margin micro-sales while keeping production costs manageable. A roast that typically sells for $18 per 250 g can generate small but steady revenue through single-serve portions priced at $1–$2. These low-commitment options allow new customers to sample your coffee without investing in a full bag, reducing purchase friction and driving repeat orders. Over time, these single-serve offerings evolve into a reliable conversion engine that feeds your broader sales channels.

For specialty roasters evaluating new product lines, the drip coffee bags have become a strategic extension of the roasting business, combining consumer convenience, brand reach, and practical commercial impact in a way that few other packaging formats can match.

How do you choose filter and drip coffee bag formats?

Success in drip coffee bags does not come from reinventing extraction theory; it comes from adopting systems that have already been validated at scale. Over time, the market has converged on material choices and dimensions that balance brewing consistency, operational efficiency, and commercial practicality.

Non-woven filter materials have become the industry standard, most commonly in the 18–25 gsm range. Their stable pore distribution, reliable tensile strength, and predictable flow behavior help minimize tearing, clogging, or uneven extraction during filling and brewing. For most roasters, this translates into fewer production variables and more consistent customer experiences. Rather than pursuing marginal flavor differences through experimental materials, many successful programs prioritize repeatability and process control, especially once volumes increase.

Size selection follows the same pragmatic logic. The widely adopted 9 × 7.5 cm rectangular filter comfortably supports standard 8–12 g doses, offering enough space for coffee expansion while maintaining controlled flow. Filters that are too small can restrict bloom and lead to sour or under-extracted cups, while oversized filters often result in thinner brews and unnecessary material waste. Relying on market-validated sizes reduces constant recalibration and keeps production stable.

At the same time, a standard does not mean rigid. For roasters developing larger-format or shared-serving products, diamond drip coffee bag filters offer additional flexibility. Sizes such as 8 × 9 cm and 9 × 9 cm allow higher coffee doses and are well suited for 1–2 cup applications, gift sets, or premium SKUs where a fuller brew volume is expected. These formats are already well established in the market and integrate smoothly into existing filling and sealing workflows when paired with the appropriate outer pouch.

Inner filter performance is inseparable from outer pouch design. Matching filters with proportionally sized pouches, ensures sufficient space for clean sealing, optional nitrogen flushing, and easy consumer handling. High-barrier laminate structures, typically combining PET for stiffness, aluminum or metallized layers for oxygen and moisture protection, and PE for seal integrity, are essential. Finely ground coffee oxidizes far more quickly than whole beans, making barrier performance critical for maintaining freshness through storage, transport, and retail display.

For roasters entering or scaling drip coffee programs, the takeaway is clear: start with proven inner–outer combinations, then expand formats strategically based on product positioning rather than experimentation alone. This approach keeps attention where it belongs, on roast quality, brand expression, and delivering a consistent cup wherever the customer chooses to brew.

Filling and sealing: strategic decisions for shelf life and ROI

Shelf life in drip coffee bags is determined less by the coffee itself than by residual oxygen, humidity exposure, and seal integrity. Even excellent beans degrade if these variables are not controlled.

For early-stage production, manual heat sealing often suffices. This approach supports pilot batches, seasonal SKUs, or small-scale testing without heavy capital investment. However, manual sealing requires careful temperature and pressure control; minor fluctuations can reduce shelf life from six months to just two.

As monthly volumes increase or products move into retail, subscription, or e-commerce channels, nitrogen-flushed sealing becomes a business-critical upgrade. By displacing residual oxygen before sealing, nitrogen flushing extends shelf life to six–twelve months and stabilizes aroma, color, and flavor. Importantly, this investment pays for itself through reduced waste, fewer quality complaints, and stronger customer retention. Most roasters consider upgrading once production reaches roughly 3,000–5,000 drip bags per month or when distribution moves beyond local, fast-turn channels.

In short, nitrogen filling is not merely a technical enhancement—it protects coffee quality, operational consistency, and, most importantly, brand trust.

Packaging strategy: From stock bags to custom branding

Outer packaging does far more than carry a logo. It defines product positioning, protects inventory quality, and determines how much operational flexibility a roaster retains as volumes grow.

Most roasters begin with stock outer drip coffee bags. These unprinted bags allow rapid market entry without long lead times or high minimum order requirements. For pilot SKUs, seasonal releases, sampling programs, or subscription inserts, stock packaging minimizes risk while preserving speed. It allows teams to focus on product validation rather than packaging commitment.

As demand becomes more predictable, many roasters adopt a transitional step by adding simple, single-color branding to stock packaging. This approach improves shelf recognition and brand recall without the complexity of full custom printing. It also preserves flexibility, enabling adjustments to roast profiles, origins, or batch quantities without being locked into large printed inventories.

The same phased logic applies to drip coffee boxes. Rather than moving immediately into fully customized cartons, roasters often start with stock boxes, paired with labels or single-color printing. This format works well for gift sets, retail trial placements, and early wholesale programs. Once volumes stabilize and SKU structures are finalized, upgrading to fully printed boxes becomes a strategic investment rather than a speculative one.

Full custom printing, whether for outer pouches or drip coffee boxes, is typically reserved for proven, high-volume products. At this stage, packaging shifts from a functional container to a brand asset, supporting consistent retail presence, clearer storytelling, and stronger visual differentiation. Importantly, this transition is driven by sales data and operational readiness, not ambition alone.

The guiding principle remains consistent: packaging complexity should scale alongside commercial confidence. Roasters who follow this staged approach maintain cash flow discipline, reduce waste, and preserve the flexibility needed to refine both product and brand as the market responds.

Common pitfalls: Why drip bags fail faster than other formats

Drip coffee bags are unforgiving by design. Unlike capsules or standard ground coffee pouches, they offer almost no buffer between production decisions and the final cup. Small misalignments in filter size, material selection, grind calibration, or sealing consistency surface immediately in brewing performance.

A slightly undersized filter can restrict bloom and choke flow, leading to sour, under-extracted cups. Oversized filters, on the other hand, often produce a thin body and weak structure, creating a perception of diluted quality. Inconsistent sealing or residual oxygen exposure can accelerate aroma loss, resulting in a product that may taste flat long before its intended shelf life.

What makes drip bags particularly challenging is that these failures are not subtle. Consumers cannot adjust grind size, dose, or brew parameters to compensate. The product either performs as intended or it does not. As a result, issues that might go unnoticed in other formats quickly translate into complaints, poor reviews, or abandoned repeat purchases.

Understanding these sensitivities early allows roasters to design a disciplined pilot workflow. By relying on proven filter dimensions, compatible outer packaging, and controlled sealing processes, teams can minimize variability before scaling up. In drip coffee bags, consistency is not a refinement. It is the foundation of commercial viability.

A practical pilot workflow for successful drip coffee bags

Successful roasters approach drip coffee bags with discipline rather than speed. The process typically begins by locking in proven filter GSM and dimensions, then calibrating grind size specifically for that filter’s flow characteristics. This sequence matters. Attempting to adapt grind to an unvalidated filter often leads to instability that compounds as volume grows.

Dosing is then optimized, most commonly within the 8–12 g range, balancing extraction clarity with production consistency. Small prototype runs are brewed and evaluated in the cup, focusing on flow rate, sweetness, mouthfeel, and finish. At this stage, the goal is not perfection, but repeatability.

Once brewing behavior is stable, early shelf-life checks at 30 to 60 days serve as a commercial reality test. These evaluations reveal whether aroma retention, seal integrity, and oxidation control are sufficient to support real-world storage and distribution, not just immediate consumption.

Initial market launches are usually supported by stock outer pouches. This limits inventory exposure while allowing roasters to gather meaningful customer feedback and observe purchasing behavior. As demand becomes predictable, specifications are standardized, waste decreases, and the workflow transitions from experimental to repeatable. Only then do most roasters introduce nitrogen flushing or custom-printed packaging, when volume and channel requirements clearly justify the investment.

This stepwise approach turns drip coffee bags from a fragile test product into a scalable, profitable line. More importantly, it creates an operational system capable of supporting seasonal releases, gifting programs, and retail expansion without compromising consistency or control.

FernPack support: From materials to market-ready drip coffee

At FernPack, we support roasters through every stage of the drip coffee bag journey, from early material selection to market-ready packaging systems. We supply food-grade inner filters, high-barrier outer drip coffee bags, and custom drip coffee boxes designed to protect both coffee quality and brand integrity. Each component is selected with one goal in mind: ensuring your coffee retains its intended aroma, flavor, and freshness, whether brewed immediately or after extended storage and shipping. Whether you are validating your first pilot batch or scaling into retail shelves and subscription programs, FernPack works as a technical partner, helping you reduce risk while maintaining consistency.

If you are planning to launch or refine a drip coffee bag line and want clarity on filter options, pouch structures, sealing methods, or cost implications, our team is available to help. You can contact us to discuss your project and request a free, no-obligation quotation tailored to your specifications.

With the right materials, sealing process, and guidance, your drip coffee bag can be more than a convenience—it can be a high-quality, compelling product that earns trust and loyalty with every brew.